| Availability: | |

|---|---|

| Quantity: | |

22X22

Solaraven

8419901000

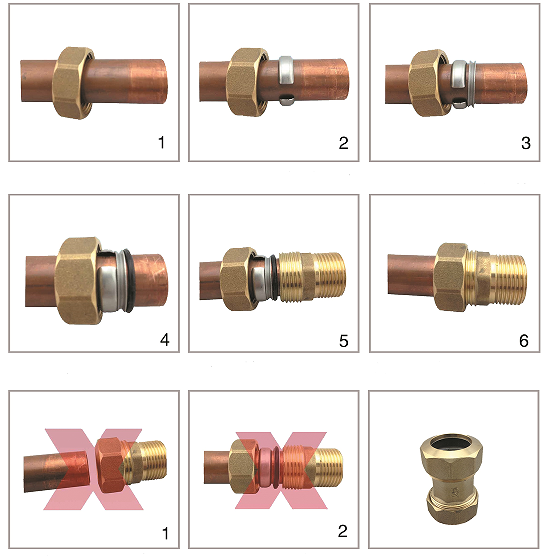

compression copper fittings connect copper pipes and plumbing system without welding.

Above compression copper fittings are used for flat plate or heat pipe solar collectors connection.

Brass compression fittings have the following advantages:

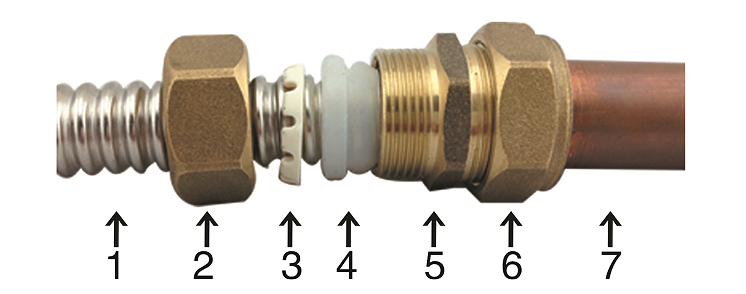

Reliable sealing performance: Brass compression fittings achieve a robust seal under high pressure or extreme conditions through a metal-to-metal seal on the ferrule or in combination with an elastic sealing ring (such as rubber or fluororubber), effectively preventing leakage. they are designed to withstand pressures up to 800 bar and maintain a durable seal in both low and high temperature environments.

Strong vibration resistance and durability: The fitting structure (such as a double-edged ferrule or elastic seal) absorbs pipeline vibration, reducing the risk of loosening and making it suitable for harsh conditions such as construction machinery or hydraulic systems.

Easy assembly and maintenance: Brass fittings typically use a ferrule connection, making assembly simple and quick without welding. Some models also offer a functional nut and built-in pre-loaded body to avoid overtightening, improving assembly efficiency and reliability.

Material Advantages: Brass possesses excellent corrosion resistance, mechanical strength, and machinability, making it suitable for various fluid environments (such as oil, gas, or water), while supporting repeated disassembly and assembly without affecting sealing performance.

Standardization and Interchangeability: Many brass compression fittings conform to international standards such as ISO, are fully interchangeable with traditional fittings, and facilitate integration into existing systems.

normally work for copper pipes diameter 22mm and also for flexible corrugared stainless steel pipes.

compression elbow and Tee

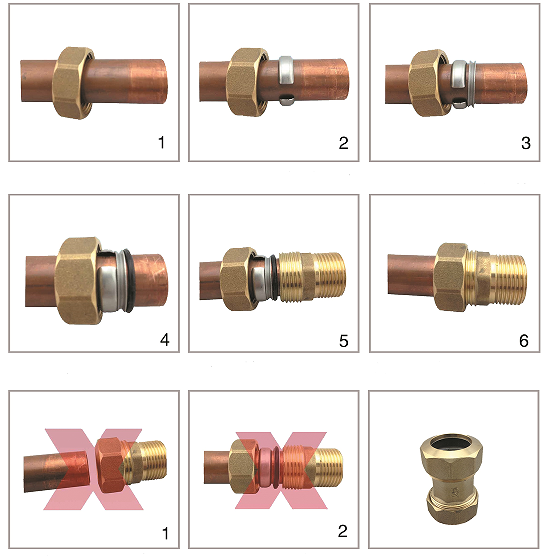

compression copper fittings connect copper pipes and plumbing system without welding.

Above compression copper fittings are used for flat plate or heat pipe solar collectors connection.

Brass compression fittings have the following advantages:

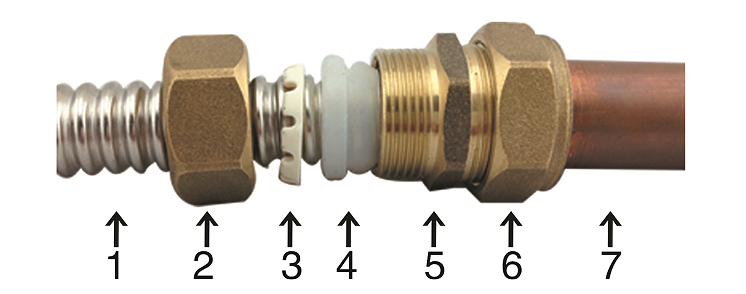

Reliable sealing performance: Brass compression fittings achieve a robust seal under high pressure or extreme conditions through a metal-to-metal seal on the ferrule or in combination with an elastic sealing ring (such as rubber or fluororubber), effectively preventing leakage. they are designed to withstand pressures up to 800 bar and maintain a durable seal in both low and high temperature environments.

Strong vibration resistance and durability: The fitting structure (such as a double-edged ferrule or elastic seal) absorbs pipeline vibration, reducing the risk of loosening and making it suitable for harsh conditions such as construction machinery or hydraulic systems.

Easy assembly and maintenance: Brass fittings typically use a ferrule connection, making assembly simple and quick without welding. Some models also offer a functional nut and built-in pre-loaded body to avoid overtightening, improving assembly efficiency and reliability.

Material Advantages: Brass possesses excellent corrosion resistance, mechanical strength, and machinability, making it suitable for various fluid environments (such as oil, gas, or water), while supporting repeated disassembly and assembly without affecting sealing performance.

Standardization and Interchangeability: Many brass compression fittings conform to international standards such as ISO, are fully interchangeable with traditional fittings, and facilitate integration into existing systems.

normally work for copper pipes diameter 22mm and also for flexible corrugared stainless steel pipes.

compression elbow and Tee

content is empty!